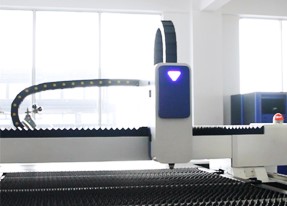

Shanghai Guanzhi Industry Co., Ltd. , established in year 2011, is specialized in laser equipment with variable sizes and models, such as fiber laser cutting machines and laser welding machines. Our strength is to offer one stop solution for metal and non-metal processing industry with our independent R&D team and professional after sale team. We have been keeping introducing the domestic as well as the overseas advanced laser technique and applications all these years. Nowadays we have been successfully in providing the OEM/ODM services to our worldwide distributors and agents. What’s more, besides the direct after-sales service from us, the technical personnel from some different countries and areas who have received good technology training from us are supporting clients’ after-sales service with the local languages as well.

GZ laser is one of the biggest suppliers of all kinds of laser equipment in China. We are mainly engaged in fiber laser cutting machine, laser welding machine, laser engraving machine, laser marking machine, etc. GZ laser has more than seven years’ history, serving more than 60 countries all over the world.

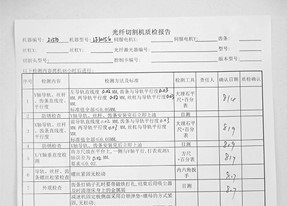

GZ laser has quality control system and quality management team, and strictly adhere to the general standards of the industry and company guidelines. Implement quality monitoring from every aspect of R&D, production and after-sales of laser equipment, to ensure that each device can meet customer’s requirements and stable running at customers’ side.

Incoming Inspection

For every part of the machine, GZ Laser will strictly control the quality. We require suppliers to provide quality inspection reports, at the same time, strict quality monitoring will be carried out when the parts are in the factory.

The width, repetition frequency and peak power of the laser pulse are detected by using the photoelectric detectors and oscilloscope.

Stability test and aging test for laser head.

Testing the flatness and straightness of the track to ensure that the machine runs smoothly.

The precision and consistency between gear and rack are mainly tested.

we will adjust the suitability of the machine through continuous empty experiments.

Process Control

The assembly process of the machine will also affect the stability of the machine while operating at customers’ side, therefore, in the process of machine assembly – from the most basic machine bed to the final assembly of the whole machine, is strictly followed by the quality management standard.

The bed frame is welding by 10mm thick and high strength square.

GZ Laser has its own gantry milling.

The straightness of guide rack is guaranteed by using laser collimator.

We install the motor reducer strictly according to standard production process and standard.

Pre-delivery Inspection

The machine will accept a number of quality testing, respectively, from the performance, stability, fitness, practical and other aspects of consideration, for non-compliance with the standard part of the arrangements for debugging and maintenance, to insure that the machine just reach its best condition before delivery.

Every component of the machine, every performance, every parameter is carefully tested.

Ensure the cutting accuracy through laser interferometer checking and 24 hours testing to make sure the machine will be in the best condition.

Before delivery, different metal materials will be cut, observing the cutting effect, and then do adjustment according to the needs, and this process lasts two weeks.

The multiple protective measures will be done for laser equipment during the packing process to ensure that each component is applicable for long distance cargo shipping.